Concrete polishing Orange County. Concrete grinding, concrete sealing. Warehouse Concrete Floors in Orange County. Garage Floor Coatings Orange County and Los angeles. Polished Concrete Floors Orange County and Garage floor epoxy Los Angeles are guaranteed to out perform store bought Epoxy for Concrete floor coatings. Concrete Polishing Orange County for Concrete Flooring in Orange County. Industrial Concrete Floor Coatings for Warehouse Floors The Kings Of Concrete www.ConcretePolishingOrangeCounty.com Floor Polishing Orange County.

Concrete garage floor coatings using concrete resurfacing and polished concrete floors are at the top of every Orange County polished concrete floor performance category Orange County.

Installation and Maintenance Costs for Polished Concrete FloorsBased on a survey conducted by the National Terrazzo and Mosaic Association for concrete floors, the information

below compares the cost per square foot of commonly used commercial flooring materials and polished concrete floors. This recent examination of flooring costs over a 20 year span illustrates not only some of the hidden costs involved in the purchase and installation of various materials, it also illustrates the dramatic difference in the cost of these materials.

Foot Cost Maint. Av. Life Cost 20 Years /Year

How can we do that? When you choose Marble Shooters Floor Coatings Concrete Floors for Industrial Concrete Coatings Warehouse Concrete Floors or concrete polishing are polished concrete you receive a product produced by craftsman. Airplane hangar epoxy Orange county, Chino, John Wayne Airport was Produced for The Military Industrial Concrete Coatings For Hangar Floors and Warehouse Concrete Floors the U.S. Government is naturally superior in quality, higher in value and better than consumer brands typically available to the public and Industrial Concrete floors Warehouse Concrete.

For any Industrial Concrete floors Coatings are great On Hard Concrete Floors.

Concrete Polishing Orange County

Industrial concrete floors in Los Angeles can be installed by The Kings Of Concrete. We do Industrial Concrete Floors. We Are Best in county PERHAPS THE WORLD! Orange County Concrete Floors.

concrete prep orange county

Concrete Polishing Orange County

We spend hours every day researching and applying the latest in lasting durable and beautiful concrete finishes. We have more than one option for your Industrial Concrete Coatings Warehouse Concrete Floors.

| Industrial Concrete Coatings Warehouse Concrete Floors. |

So we are confident that concrete floors can help you to make the correct choice for Industrial Concrete Coatings and Concrete Floors. We will make your garage your warehouse or your living room the easiest surface to clean and perhaps the most beautiful! Industrial Concrete Floors. We are a family owned business we share over 50 years of working knowledge. Your satisfaction means everything to us. We take pride in our workmanship and count on your referrals for more than 70% of our business. We are AA rated with the better bussiness bureau and licensed with the State Of California. Industrial Concrete Floors.

Industrial Warehouse Concrete Floors Warehouse Concrete Floors Orange County

Industrial Concrete FloorsConcrete Polishing Orange County |

A solution is applied on your plain floors to make them shiny and smooth, leaving it an easy-maintenance part of your establishment. In addition, concrete polishing is a decorative flooring solution that can greatly improve the over-all appearance of your buildings. Plus, your concrete floors will be so durable there will be no need to make repairs in a long time. We also do concrete resurfacing to make old slabs look better and be more durableIndustrial Concrete Coatings Warehouse Concrete Floors for . Our services also include concrete waterproofing and other flooring solutions.

All the services mentioned above are provided by one of the most superior contractors in the flooring industry! With over two decades of professional experience in the trade, The Kings Of Concrete By Marble Shooters is now one of the nation’s finest companies that provide excellent and superior services in all flooring needs. We guarantee to bring results that even exceed your expectations. You don’t have to settle for the ordinary on Industrial Concrete Coatings Warehouse Concrete Floors orange countyConcrete floors need to be applied with coatings because people walk all over them without much regard to their preservation. In other instances, they are exposed to seepage and moisture intrusion. As a result, these concrete floors would slowly erode because they are not tightly sealed under a waterproof coating, epoxy floor coating or concrete floor and garages need to be applied with garage floor coating since these are always under pressure with cars constantly passing over them. Without quality floor coatings, renovation that should take place in a longer period of time tends to happen earlier than expected. Then, there would be a loss of money and investments for Industrial Concrete FloorsAnother factor that should be considered is the use of Industrial Concrete coatings Warehouse Concrete Floors. When deciding on what materials to use in constructing your dream house or industrial building, the basic things that you should prioritize is the quality and durability. Constructing buildings that are intended for business or manufacturing should make use of industrial Concrete Coating Warehouse concrete Floors. Note that using a lesser kind of coating will greatly affect your investments. So, invest properly and wisely. Not only would these coatings make your building attractive but it would maintain its foundation longer than you expect. Making use of materials that were well-thought of and designed will reinforce your facilities against any industrial hazards or extreme climate and weather changes.Concrete Industrial Concrete Floors is one of the most resilient types of construction material but undoubtedly; it is also vulnerable to destruction. In time, there will be damages on its surface that leaves very unwanted and unsafe conditions. As a natural resort, people will replace it with a new one. But wait, innovated machinery and highly improved technology allows us to do things that were not available and possible before. Now, we can repair and improve damages by simply resurfacing it. With this move, we can economize and have a practical solution that is of high-quality and excellent durability on Industrial Concrete Coatings Warehouse Concrete Floors Concrete Polishing Orange County

Orange County Concrete Floors

Concrete Polishing Orange County Industrial Concrete Coatings Warehouse Concrete Floors are one of the most resilient types of construction material but undoubtedly; it is also vulnerable to destruction. In time, there will be damages on its surface that leaves very unwanted and unsafe conditions. As a natural resort, people will replace it with a new one. But wait, innovated machinery and highly improved technology allows us to do things that were not available and possible before. Now, we can repair and improve damages by simply resurfacing it. With this move, we can economize and have a practical solution that is of high-quality and excellent durability on your concrete floorAt present, establishments in Los Angeles and Orange County Industrial Concrete Floors are resorting to many innovative methods to preserve their investments. They want every part of their facilities be made of the best materials and installed with meticulousness care are very important Industrial Concrete Floors part of structures because they are constantly exposed to wear and tear. Nowadays, various types of floorings are found in the market and one of the highest in-demand is Industrial Warehouse Concrete Floors. Orange County Concrete Floors

THE KINGS OF CONCRETE

Industrial Concrete Floors The truth of the matter is to make an informed decision you need two things;

Knowledge and Choices. We can provide you both; with over twenty years of experience in concrete & amp; stone we have seen it all and tried it all. From initial concrete design, to color and pattern cuts, together we will design the perfect floor for you. Industrial Concrete Floors With options ranging from Polished, Stained, Dyed, and Industrial Concrete Floors we can provide the solution that is custom tailored to your specific needs.

Please review our pictures by clicking on the icons below. If you would like a free estimate or if we can assist in answering any questions you might have please do not hesitate to call or email. It is our pleasure to serve you.

We transform your existing concrete slab into a high shine, low maintenance work

of art. Using the latest technological advancements such as: Diamond grinders,

concrete consolidators, dyes, stains, and sealers, we can turn your concrete

into a unique work of art. Offering the look and durability of stone without the

extensive maintenance or high price tag.

When it comes toIndustrial Concrete Coatings Warehouse Concrete Floors, not all flooring is created equal. Many competitors or big-box stores use low grade coatings that are designed to keep costs down

instead of perform or last. We use all industrial grade products that are designed to cover, seal, and enhance your existing .Industrial Concrete Coatings Warehouse Concrete Floors Our 100% solids epoxy is the base of our chip system and is sealed with a two-part solvent based polyurethane top coat that is impervious to UV rays, oil, and even hot tires. Providing a superior floor covering that is guaranteed to last.

Staining and sealing is the most affordable way of transforming your existing

Concrete Floors into a finished floor. Using an acrylic color, dye, or acid stain we

can quickly convert your old dingy concrete slab to a beautiful piece of decorative concreteIndustrial Concrete Coatings Warehouse Concrete Floors . You can even choose your finishes; from matte, satin, all

the way to high gloss. Sealer choices include: Acrylic, Epoxy, Impregnator, or

Polyurethane. Stain & Sealed Concrete is the must have option for all the bare

Industrial Concrete Coatings Warehouse Concrete Floors in your life.

Using saw cuts and multiple color schemes we can create a personalized work of

art that will have people second guessing on what kind of surface they are

looking at Industrial Concrete Floors. Patterns and colors can be tailored to make everything from shapes

to logos on your Industrial Concrete Floors Helping re-create the beauty and uniqueness of stone that will no

doubt leave a lasting impression with everyone that views it.

|

|

Industrial Concrete Coatings Warehouse Concrete Floors Anaheim and Fullerton

Concrete floor Industrial Concrete Coatings Warehouse Concrete Floors

-

Anaheim

-

Baldwin Park

-

Banning

-

Shady canyon

-

Beverly Hills

-

Burbank

-

Cathedral City

-

Cathedral City

-

Corona

-

Costa Mesa

-

Cypress California

-

Diamond Bar California

-

Downey California

-

Fullerton California

-

Garden Grove California

-

Glendale

-

Glendora California

-

Hollywood California

-

Huntington Beach

-

Inglewood California

-

Irvine California

-

Laguna Hills Beach

-

Loma Linda

-

Los Angeles

-

Mission Viejo California

-

Newport Beach

-

Norco California

-

Ontario

-

Palm Springs

-

Pasadena California

-

Rancho Cucamonga

-

Redlands

-

Riverside

-

San Dimas California

-

San Juan Capistrano

-

Santa Ana

-

Santa Clarita California

-

Santa Monica

-

Seal Beach California

-

West Covina California

More department stores, manufacturing companies, hotels, restaurants and even airports are using the Polished Concrete. This just proves that that more people sees the benefits and beauty of concrete polishing. It also goes to say that concrete polishing does not have to be confined in doors, it can also be used out doors Industrial Concrete Coatings Warehouse Concrete Floors.

Dull gray cement floors are gradually changing into a work of art Industrial Concrete Coatings Warehouse Concrete Floors. As more people enjoy the beauty of concrete polishing, day by day there are new ways to enhance it Industrial Concrete Coatings Warehouse Concrete Floors your. Just to site a few, you can stain it, add die to it, and arrange glass, nails or bolts to create a design. You can even have your Industrial concrete coatings warehouse concrete floors. Have an old concrete floor Industrial Concrete Coatings Warehouse Concrete Floors ?. Then you might consider Concrete Polishing as an alternative solution. Decorative Industrial Concrete Coatings Warehouse Concrete Floors can turn your plain concrete into stylish floors that look nice. Bring new life to your concrete floors with Concrete Grinding, removing scratches and add a design pattern to your floor. Nothing is better for a bare concrete floor than Polished Concrete, you will be amazed at the difference. Industrial Concrete Coatings Warehouse Concrete Floors

The purpose of this article is to inform readers of the qualities a waterproofing concrete sealerIndustrial Concrete Coatings Warehouse Concrete Floors should have. We’d like to share this information with you to enable you to make the most informed decision when purchasing a waterproofing concrete sealer for your basement, home, or Industrial Concrete Coatings Warehouse Concrete Floors commercial building. Today, there are few exceptional products on the market that are not only convenient in that they can be applied both above and below grade, but they are affordable, long lasting Industrial Concrete Coatings Warehouse Concrete Floors , and environmentally friendly. Before we go into detail about properties a quality waterproofing concrete sealer should have, we’ll discuss what a concrete sealant does. Industrial Concrete Coatings Warehouse Concrete Floors Concrete Polishing for Industrial Concrete Coatings Warehouse Concrete Floors is a process for turning a concrete floor into a highly abrasion resistant, incredibly dense, smooth and visually appealing surface on industrial concrete coatings warehouse concrete floors densify a concrete floor through a process of diamond grinding and application of chemicals to a hardness much greater than that of a common concrete slab. The result is an extremely hard surface with a beautiful shine requiring very simple maintenance. If you have a floor need and are considering whether Industrial Concrete Coatings Warehouse Concrete Floors would be the right fit please explore our webiste and take advantage of the resources here. on Industrial Concrete Coatings Warehouse Concrete Floors

In conjunction with grinding the floor, chemicals are often used called concrete densifiers or hardeners. These products react with the soluble calcium compounds in the cement to create insoluble calcium silicates. This process fills in many of the pores in the concrete creating a surface with much greater hardness.

If a more decorative finsh is desired the concrete can be dyed as part of the grinding process. Decorative patterns can also be cut into the surface to create tile effects. Another popular and beautiful look is that of exposed aggregate. If the concrete is ground more aggressively the aggregate stone in the concrete can be exposed. This is a look similar to terrazzo. One of the best features of any of these decorative finishes is that they are not coatings. Coatings have significant limitations and are prone to failure.

Polished Concrete Floors

Concrete has long been known for its durability and cost-saving features. With modern technologies, homeowners and business owners are finding they can harness these advantages of concrete in their floor along with many other added benefits. Polished concrete on Industrial Concrete Coatings Warehouse Concrete Floors is a popular alternative to other flooring materials because of three noteworthy benefits: lower total cost, lower maintenance, and aesthetics.

Polished concrete’s superior durability and performance have made it a top finish for retail stores, warehouses, office facilities, and municipalities. Homeowners, as well, are selecting these smooth, high-luster floors that imitate the look of polished stone on Industrial Concrete Coatings Warehouse Concrete Floors.

Polished concrete floors are very economical. Unlike many other floor surface materials, a polished concrete floor can last up to ten years or longer before it needs to be refinished. Maintenance on a polished floor is also minimal, thereby reducing costs associated with keeping floors clean, durable, and traffic-friendly for Industrial Concrete Coatings Warehouse Concrete Floors.

Polished concrete floors are striking in appearance. The exposure of the aggregate in the concrete unveils a look of stone. There are a variety of colors available on the market to stain or in some other way modify the color and look of the polished floor. There are also various levels of sheen depending on the degree of reflectivity and shine that is desired.

1. Construction of a structure with a stained concrete floor is really no more difficult or demanding than the case of any other flooring as long as a few common sense rules are observed to preserve the natural beauty of the concrete.

2. Do not mark or discolor the floor with paint, siliconeoil, plumbers glue, purple primer, masking tape, gasoline, sheetrockmud, red or blue chalk, grease pencil, magic marker, ink pens, and anything else you would not get all over a hardwood floor.We do have techniques that can remove some of these blemishes, however, this will not yield perfect results, it is costly and should be avoided.Industrial Concrete Coatings Warehouse Concrete Floors

3. Driving nails into the floor for wall braces will result in big ugly holes when you remove the nails. Plan “A” do not drive nails into the floor, plan “B” if you drive a nail into the floor “DO NOT REMOVE IT!!!” We can remove them without making the big ugly holes. We suggest bracing the walls by nailing the foot of the brace to the baseplate of the opposite wall.Industrial Concrete Coatings Warehouse Concrete Floors

4. Never pour acid of any kind on the floor. Acid will neutralize the lime in the concrete making it inert and unstainable.Industrial Concrete Coatings Warehouse Concrete Floors

5. Avoid cutting plywood,siding, USB etc. on a 2×4 laying on the concrete. The blade can strike the concrete when the plywood flexes making ugly irregular scoremarks on the concrete.Industrial Concrete Coatings Warehouse Concrete Floors

6. Never put tape on the floor! Tape will pull up tiny particles from the concrete surface when it is removed. When these areas are stained they will be darker than the rest of the floorand shaped exactly like the piece of tape that was on the concrete.Industrial Concrete Coatings Warehouse Concrete Floors

7. Do not leave nails or other metal objects on wet concrete. The nails will rust and leave nail shaped dark red spots on the floor. Similar blemishes can occur if lumber is left lying on the concrete in wet conditions.Industrial Concrete Coatings Warehouse Concrete Floors

8. Orange chalk should be used to srike lines for laying out walls etc. The good thing about orange chalk is that water washes it away completely. Never use blue chalk as it cannot be removed and can easily be seen through most concrete stain colors. Red chslk is also permanent and should be avoided.Industrial Concrete Coatings Warehouse Concrete Floors

Industrial Epoxies and Coatings

1) They resist pet stains and odors Industrial Concrete Coatings Warehouse Concrete Floors .Orange County Concrete Floors

1) They resist pet stains and odors Industrial Concrete Coatings Warehouse Concrete Floors .Orange County Concrete Floors

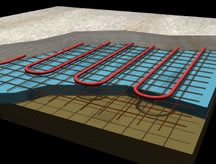

5) You can heat them.

5) You can heat them.

Indoor concrete floors(light cleaning) –

Indoor concrete floors(light cleaning) – Outdoor concrete(heavy cleaning)

Outdoor concrete(heavy cleaning)