Concrete Dye in its “natural” state is a porous product that is susceptible to efflorescence, spalling and dusting; and it does not provide an aesthetic finish, nor is it easily cleaned. That’s why stained concrete Products has created a science and art that revolves around the conversion of concrete from being a plain, boring, and porous industrial floor, to being one of strength, longevity and beauty. Rather than continually having to cover up the floor and trying to hide the inherent problems, only to create new ones, our skilled stained concrete Certified Applicators create a stained concrete floor that meets your long-term needs. Through the use of our patented process of diamond grinding and polishing, in conjunction with the specially formulated RetroPlate, we eliminate your need for all topical sealers on stained concrete. We eliminate moisture vapor problems. Bottom line: Look at the true costs of the product that you choose…and RetroPlate will generally be your cost effective choice. Short term or long term: we deliver the best stained concreteTrends in Stained Concrete Drive through any neighborhood and note that most have common gray Stained concrete driveways! In the sixties and prior, Orange County homes were built with asphalt driveways, and they were considered to be the standard, until stained concrete replaced them.Increasingly over the years the bar has been raised as people have opted for brick ribbons, stone ribbons, pavers, stamped concrete etc… All of which are beautiful but also very expensive and can cost as much as $15,000 per driveway. Each of them have their pros and cons. For instance brick and stone ribbons, and especially pavers, create many nooks and crannies for weeds to grow (and they do).Some reasonably priced alternatives have been catching on for the last few years, which include:

Stained concrete– Simi transparent stains that are layered and that work with the existing shades of the stained concrete and then topped with a beautiful clear coating.

Stained Concrete Overlay – Stained Concrete based coatings that are colored and then stamped to achieve the texture of tile or stone.

Stained Concrete Scoring or Engraving – Grout lines can be cut and then filled with grout to achieve the appearance of large tiles or stones. Any of these options can be accomplished at a fraction of the cost of a demo and re-pour.All of these options can effectively transform that common gray driveway or patio into a beautiful stone courtyard stained concrete.

Stained Concrete | Stained Concrete Polishing | Stained Concrete Resurfacing

If you recently ripped out carpet, tile, or linoleum, or your pool deck and driveway are all cracked up, there is a remedy. Stained Concrete , polishing, and Stained concrete overlays make your existing Stained concrete beautiful again.

Stained Concrete

For a mottled, variegated look, stained concrete is the way to go. We have a wide pallete of colors to match any architectural style. Choose either glossy or satin finish. Stained concrete, interior or exterior, is an easy way to add value to your property.

Stained Concrete Polishing

Seained Concrete polishing means grinding your concrete floors with finer and finer grit diamonds. Stained concrete polishing leaves a smooth, glossy interior floor that lasts for years. Polished concrete can also be stained. Polished concrete is for interiors, only.

Stained Concrete Resurfacing

Stained concrete resurfacing is a way to turn your messed up slab into a fresh canvas. We apply a thin concrete microtopping that can be changed to the natural look of flagstone, slate, or marble without the expensive mess. We can also create a sleek, ultra modern look. Every slab becomes a unique, one-of-a-kind bit of art that reflects the personality of its owner.

Concrete Finishing

Whether you want glossy, haute-couture floors or a natural, satin finish, Coolstone Concrete Design and Resurfacing can create it for you. All without expensive tear-out and demolition.

Some benefits of concrete resurfacing:

1. About half the cost of tear-out and pouring new

2. Hypoallergenic

3. Eco-friendlystained concrete, with less natural resources used in production

4. Completely customizable stained concrete

5. Easy to clean stained concrete

What Colors Are Available, and How Do I Pick the Right One? For Stained Concrete.

With acid stains, your color choices will be limited. Most manufacturers offer only eight hues, mostly subtle earth tones, such as tans, browns, terra cottas, and soft blue-greens. Although the basic color palette is sparse, you can mix two or more stain colors before application to achieve a different shade or apply one color over another. You can also produce deeper color effects with a stain by applying two coats. Water-based acrylic stains come in a much broader spectrum of hues. Most manufacturers offer dozens of standard colors, including black and white and even metallic tints. Here, too, the different colors can be mixed, like water-based paints, to broaden your options on stained concrete.

Cleaning concrete is easy and is an important step towards prolonging the life of your beautiful floors, countertops, patios, or other polished concrete. Here are some tips for cleaning your concrete to keep it

looking beautiful. Regular maintenance and concrete cleaning are necessary to keep your concrete looking as fresh and beautiful as the day it was finished. Over time, dirt that is not removed from the surface of the concrete will make its way further into the concrete and could cause significant damage. Don’t waste thousands of dollars refinishing your concrete if you don’t have to. Your local contractor can introduce you to many affordable methods of cleaning your concrete and restoring it to its original beauty and luster

Indoor concrete (light cleaning) – Indoor concrete (light cleaning) –

When beverages and other liquids are spilled on concrete, they may leave noticeable spots. Usually soap and water will be enough to clean cola, coffee, and other beverages out of your concrete. For tougher spots, your contractor can help. Cleaning tough spots without ruining the paint, epoxy and stamping on your floor is a delicate project that requires special cleaners and tools; cleaners that are tough enough to get out the stain, yet gentle enough to keep your decorative floor intact.If your concrete has become dirty with mold and mildew, identified by patchy black spots, don’t lose hope, this too can be cleaned with the help of your contractor. Mold and mildew can spread throughout your home quickly and mold spores can cause many illnesses including asthma and irritable bowel syndrome. If you suspect that you have mold or mildew on your concrete, be sure to contact a contractor immediately before your family’s health is impacted. Since mold and mildew are caused by moisture, your contractor may also check the surrounding area for any leaks that could be causing the excess moisture.

Outdoor concrete (heavy cleaning) Outdoor concrete (heavy cleaning)

When dirt, dust, and grime collect on your outdoor concrete surface, it may begin to look black or brown in appearance. Whether you’ve got tobacco stains, charcoal, soil or other outdoor debris on your concrete, your contractor knows how to get it out without leaving any indication that it ever existed. Sometimes, black or brown spots on your concrete can be oily—especially on concrete used in a garage or as a driveway. Because oil and grease are so difficult to remove from stained concrete, harsh and toxic chemicals are used. Calling in a contractor is imperative since the harsh chemicals may damage your concrete or your health if not handled properly.

For many difficult stains and dirt spots, steam cleaning and water blasting are safe, non-toxic and effective cleaning methods. The equipment used for steam cleaning stained concrete and power cleaning can be unwieldy and expensive. Additionally, too much concentrated focus with a power washer on your finished concrete could damage the paint or stamping on the surface. Your contractor has all the appropriate equipment and experience to clean these stains without damaging your stained concrete. We are expanding and developing many new techniques and products for the Concrete Polishing Industry. The industry is in a crucial point as there are many contractors that do subpar work and call it “Concrete Polishing.” Thus a need for an independent technical institute that “IT IS THE INTENT OF THE INSTITUTE to establish standards for Stained Concrete through accreditation, and to provide quality education and support for Architects, Engineers, General Contractors, Property Owners, Interior Designers, and Concrete Processing/Polishing Contractors/ stained concreteThe Concrete Polishing Association of America has also:

- ✓Defined the processing process and its complexities.

- ✓Defined the functional and aesthetic advantages and disadvantages of ground, honed and polished stained concrete.

- ✓Defined the flooring options available when processing concrete to a desired finish.

- ✓Brought true craftsmanship and professionalism to the concrete processing industry through contractor evaluations, accreditations and training.

- ✓Developed written specifications that provide the desired results for the customer to include the concrete mix design, placement, finishing, joint layout, the ground, honed or polished finish to protection.

- ✓Provided tools for contractors to further develop their business in sales, marketing, estimating, business operations and development, including meeting the American Institute of Architects (AIA) Continuing Education System (CES) credit requirements for stained concrete

Stained Concrete Coatings NC

Stained Concrete

This retail store’s beach and ocean theme was enhanced with a variegated concrete floor. Using a turquoise acid stain, Matt Hine of Progressive Concrete Coatings in Wilmington, NC, was able to incorporate the aqua color of the store’s logo into the Stained concrete .

Stained concrete

Finished concrete saves energy in several ways. In the summer time, a slab in contact with the ground draws the earth’s own natural cooling abilities into the building. In the winter, if a building has been designed to expose the slab to natural sunlight, it will soak up this radiant heat. Then at night the slab will release the heat into the building to provide a more uniformly warmer interior. Both of these are examples of concrete’s inherent thermal mass capability, which save money on heating and cooling costs.

Stained concrete

Finished stained concrete saves energy in several ways. In the summer time, a slab in contact with the ground draws the earth’s own natural cooling abilities into the building. In the winter, if a building has been designed to expose the slab to natural sunlight, it will soak up this radiant heat on stained concrete. Then at night the slab will release the heat into the building to provide a more uniformly warmer interior. Both of these are examples of concrete’s inherent thermal mass capability, which save money on heating and cooling costs stained concrete  There are services available to have your stained concrete floor colored and textured to resemble almost anything you can put on a floor. Rich and lifelike colors will give new life to your concrete slab, and set it up to fit the decor of the rest of your home, office, or wherever. Want a hardwood floor without having to worry about dry rot or constant water damage? Want tile without having to replace it every so often due to the frailty of the surface? If you’re looking for these textures, or a number of others, Decorative Stained concrete can probably give you what you’re looking for The short answer is that it’s the best way to turn a floor that looks like it was poured for a garage into a floor that looks like it was designed for a palace. Imagine turning a plain concrete surface into a floor that gleams like marble!

Stained Concrete

The short answer to concrete polishing is that it’s the best way to turn a floor that looks like it was poured for a garage into a concrete polishing floor that looks like it was designed for a palace. Imagine turning a plain concrete surface into a floor that gleams like marble! dedication to detail, state of the art equipment, and pride taken in workmanship are why you need to call on Marble Shooters for your Concrete Polished needs. At Marble Shooters we work around your busy schedule, causing little or no down time. Experience, reliable, and efficiency add to making your decision to hire Marble Shooters the right decision. New concrete or existing, clear application or dyed our customers are amazed with the finish Marble Shooters is capable of producing beautiful Stained Concrete

The Kings Of Stained Concrete and Marble Shooters. We Are Best in Kingdom and County. PERHAPS THE WORLD!

We spend hours every day researching and applying the latest in lasting durable and beauitful concrete finishes. We have more than one opition for your floor. So we are confident that we can help you to make the correct choice. We will make the garage stained concrete and your warehouse or your living room the easiest surface to clean and perhaps the most beautiful! We are a family owned business and we share over 50 years of working knowledge. Your satisfaction means everything to us. We take pride in our workmanship and count on your referrals for more than 70% of our business. We are AA rated with the better bussiness bureau and licensed with the State Of California.

Ask to see the colored charty for stained concrete

Stained Concrete floor poliahing or coatings are one of the most resilient types of construction material but undoubtedly; it is also vulnerable to destruction. In time, there will be damages on its surface that leaves very unwanted and unsafe conditions. As a natural resort, people will replace it with a new one. But wait, innovated machinery and highly improved technology allows us to do things that were not available and possible before. Now, we can repair and improve damages by simply resurfacing it. With this move, we can economize and have a practical solution that is of high-quality and excellent durability on your Stained concrete floorAt present, establishments in Los Angeles and Orange County are resorting to many innovative methods to preserve their investments. They want every part of their facilities be made of the best materials and installed with meticulousness. Stained Concrete Flooring is very important part of structures because they are constantly exposed to wear and tear. Nowadays, various types of floorings are found in the market and one of the highest in-demand is Stained concrete

MARBLE SHOOTERS

THE KINGS OF CONCRETE

The truth of the matter is to make an informed decision you need two things;

Knowledge and Choices. We can provide you both; with over twenty years of

experience in concrete & stone we have seen it all and tried it all. From

initial concrete design, to color and pattern cuts, together we will design the

perfect floor for you.

With options ranging from Polished, Stained, Dyed, and Coated Concrete we can

provide the solution that is custom tailored to your specific needs.

Please review our pictures by clicking on the icons below. If you would like a

free estimate or if we can assist in answering any questions you might have

please do not hesitate to call or email. It is our pleasure to serve you.

Options

Polished Stained Concrete:

We transform your existing concrete slab into a high shine, low maintenance work

of art. Using the latest technological advancements such as: Diamond grinders,

concrete consolidators, dyes, stains, and sealers, we can turn your concrete

into a unique work of art. Offering the look and durability of stone without the

extensive maintenance or high price tag.

Concrete Coatings:

When it comes to coatings, not all flooring is created equal. Many competitors

or big-box stores use low grade coatings that are designed to keep costs down

instead of perform or last. We use all industrial grade products that are

designed to cover, seal, and enhance your existing concrete slab. Our 100%

solids epoxy is the base of our chip system and is sealed with a two-part

solvent based polyurethane top coat that is impervious to UV rays, oil, and even

hot tires. Providing a superior floor covering that is guaranteed to last.

Stain & Sealed Concrete:

Staining and sealing is the most affordable way of transforming your existing

concrete into a finished floor. Using an acrylic color, dye, or acid stain we

can quickly convert your old dingy concrete slab to a beautiful piece of

decorative concrete. You can even choose your finishes; from matte, satin, all

the way to high gloss. Sealer choices include: Acrylic, Epoxy, Impregnator, or

Polyurethane. Stain & Sealed Stained Concrete is the must have option for all the bare

concrete in your life.

Design:

Using saw cuts and multiple color schemes we can create a personalized work of

art that will have people second guessing on what kind of surface they are

looking at. Patterns and colors can be tailored to make everything from shapes

to logos. Helping re-create the beauty and uniqueness of stone that will no

doubt leave a lasting impression with everyone that views your stained concrete.

|

Why Concrete Floors Are Pet-Friendly

|

|

|

|

|

Dear Roy,

Your clients who have pets consider them to be important members of the family, and will often think about the needs of their four-footed companions when choosing the flooring materials they use in their home. This is a great selling point for concrete, since few flooring materials are friendlier to pets and their owners than concrete. Not only do concrete floors stand up well to claws and muddy paws, they can also contribute to pet comfort and health.

|

|

Stained Concrete

1) They resist pet stains and odors. 1) They resist pet stains and odors.

When the pores in concrete are sealed with a protective film-forming sealer or floor finish, pet urine can’t seep into the floor and leave behind lingering odors and stains.

2) They are easy to clean.

When family pets shed fur or race through the house with rain-soaked or muddy paws, cleaning up after them is no sweat if the floors are concrete. Tell homeowners that they can simply give the floor a few swipes with a broom, towel or mop, and the mess is history. See Caring for Concrete Floors.3) They won’t trap pet dander, fleas or mites.

In addition to fur, pets shed animal dander that can aggravate allergies in people who are sensitive. Smooth floor surfaces like concrete won’t trap this dander the way carpet will, making the dander easy to remove during routine cleaning. Concrete floors also won’t harbor fleas or mites that pets may carry into the home. (For more information, watch the video Controlling Allergen)4) They are nontoxic.

Synthetic carpets can emit volatile organic compounds, or

VOCs, as can some carpet adhesives and padding. Some of

the adhesives used under vinyl sheet goods and linoleum can

also emit VOCs. Concrete floors, stained with nontoxic

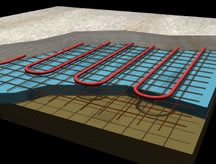

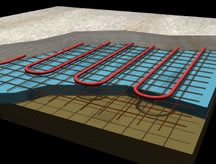

pigments, do not release VOCs that can be harmful to homeowners as well as their pets. 5) You can heat them. 5) You can heat them.

Because hot air rises, many homes tend to be colder at floor level. And since that’s where pets spend most of their time, the ability to warm up concrete floors with radiant heating will keep them comfortable while saving the homeowner big money on energy bills.6) They are scratch resistant.

Rambunctious pets and their claws can really scratch up hardwood flooring. Concrete floors are inherently scratch resistant, and when protected with a good sealer or floor wax, they are virtually scratchproof. View this chart comparing the performance of polished Stained concrete sealers. |

Concrete Polishing for concrete floor is a process for turning a concrete floor into a highly abrasion resistant, incredibly dense, smooth and visually appealing surface. Stained Concrete

Comparative Installation and Maintenance Costs for Polished Concrete FloorsBased on a survey conducted by the National Terrazzo and Mosaic Association, the information

below compares the cost per square foot of commonly used commercial flooring materials and polished concrete floors. This recent examination of flooring costs over a 20 year span illustrates not only some of the hidden costs involved in the purchase and installation of various materials, it also illustrates the dramatic difference in the cost of these materials.

Costs per Square Installed Annual Years Replacement Total Exp. Cost PSF

Foot Cost Maint. Av. Life Cost 20 Years /Year

Vinyl Sheet Flooring $2.72 $1.39 9 $3.43 $38.14 $1.91

Vinyl Tile Flooring $1.23 $1.47 15 $1.60 $32.76 $1.64

Ceramic Mosaic Tile $6.48 $1.22 20 $30.88 $1.54

Quarry Tile $5.78 $0.58 20 $30.18 $1.51

Cement Terrazzo $8.50 $0.46 20 $20.10 $1.01

Granit-Glaze $6.50 $0.46 20 $15.70 $0.79

PolishedCrete $3.98* $0.00 20 $3.98 $0.19

Polished Concrete Floors

Concrete has long been known for its durability and cost-saving features. With modern technologies, homeowners and business owners are finding they can harness these advantages of concrete in their floor along with many other added benefits. Polished concrete is a popular alternative to other flooring materials because of three noteworthy benefits: lower total cost, lower maintenance, and aesthetics.

Polished concrete’s superior durability and performance have made it a top finish for retail stores, warehouses, office facilities, and municipalities. Homeowners, as well, are selecting these smooth, high-luster floors that imitate the look of polished stone.

Polished concrete floors are very economical. Unlike many other floor surface materials, a polished stained concrete floor can last up to ten years or longer before it needs to be refinished. Maintenance on a polished floor is also minimal, thereby reducing costs associated with keeping floors clean, durable, and traffic-friendly.

Polished concrete floors are striking in appearance. The exposure of the aggregate in the stained concrete unveils a look of stone. There are a variety of colors available on the market to stain or in some other way modify the color and look of the polished floor. There are also various levels of sheen depending on the degree of reflectivity and shine that is desired onyour stained concrete

One of the most difficult (if not the most difficult) problems in the industry is edge work. Anyone who has done any concrete polishing will tell you that there is still no good solution for edges. Oftentimes, the edge work will end up being done by hand, and it is an art in itself to learn to blend the edges in with the rest of the floor. Many contractors won’t take jobs with relatively small amounts of square footage if there will be a great deal of edge work. You definitely want to take into consideration the amount of time you will spend doing edges in relation to the square footage of the job. Also, make sure the customer understands the nature of the beast with edges, their impact on price, and what to expect as far as aesthetics. Installing epoxy on the edges is often a great alternative to polishing them, but even with epoxy, you will still have to do some light grinding on the edges and prep them.

Most existing concrete has been abused. Chips will not go away entirely unless you grind away a great deal of concrete at a great deal of expense. Concrete in poor condition will require more labor and will have more flaws. Concrete in poor condition will also be rough on your tools. These flaws won’t necessarily look bad. They are what I consider to be part of the natural element in concrete, like the natural elements in a slab of marble or granite. However, the customer needs to know exactly what to expect, and you can’t price these jobs too low.

The waviness of the concrete will very much affect the ease of polishing and the outcome of your job. Wavy concrete floors are nothing rare. Some spots will be hard to reach, and your floor will require more work to be finished and will still not have an even look at the end. Unless you have a controlled pour, let the customer know that aggregate will vary a great deal throughout the floor. Expect to see large aggregate pieces in the joints and high spots and smaller aggregate in the rest of the floor. Make sure the customer understands this before you agree to do the job. The higher your high spots, and the more you need to grind them down, the larger the visible aggregate will be in those areas. Steer away from dealing with exposed aggregate on wavy floors.

Laser-leveled concrete is much easier to polish. You can charge less for these floors. Most of the new concrete poured for industrial or commercial use now is laser-leveled. It is in renovation work that you are more likely to run into wavy floors.

Some of the concrete floors poured now are also power-troweled to the point of being overtroweled for polished concrete. Some concrete is so overtroweled that it is almost burned, and it is either extremely difficult to polish or cannot be polished. Make sure you don’t make a commitment to polish a floor that cannot be polished.

When VCT (vinyl composite tile) is taken up, it often leaves ghost lines. These lines may not go away. Your customer will need to be aware of this ahead of time.

Soft concrete will cost you more to polish than hard concrete. You should perform a hardness test before pricing any job. Soft concrete will require hard metal-bond diamond tooling. That tooling will still wear out faster, so you’ll go through more of it — in some cases, a great deal more of it. This holds true for your metal-bond and your resin-bond diamond tooling, adding cost to your job.

If your customer is requesting an exposed aggregate floor, make sure they understand the aggregate will not be evenly exposed. What already lies within the concrete, as it lies there, will be exposed. Also make sure you charge considerably more, as more labor and tooling will be required. If the concrete floor is uneven or wavy, this will become even more of an issue. If it were me, I’d have a customer sign off on such work. In today’s environment, it is wise to make sure that everyone is on the same page. You don’t want to end up in a lawsuit over unrealistic expectations. It’s always better to underpromise and overperform.

Take into consideration dust as well as possible labor expenses for cleaning. Whether a vacuum system can make concrete grinding and polishing 99 percent dust-free is questionable. There will be dust, and quite a bit of it. In a setting such as an airport, retail store, or anywhere else where the public will encounter the dust, you must make sure you minimize this issue. You may have to clean at the end of every day. Understand that the last thing the end user needs is a lawsuit, not to mention the appearance of a very dusty environment. Also make sure your employees have dust masks available to them. Concrete dust can cause silicosis.

These are all good things to keep in mind while you are pricing your first concrete polishing jobs. You will get better and better at it as you gain experience. Just as it is true that concrete polishing is an art that has to be learned with experience, pricing for polished stained concrete

|

Indoor concrete (light cleaning) –

Indoor concrete (light cleaning) – Outdoor concrete (heavy cleaning)

Outdoor concrete (heavy cleaning)

There are services available to have your stained concrete floor colored and textured to resemble almost anything you can put on a floor. Rich and lifelike colors will give new life to your concrete slab, and set it up to fit the decor of the rest of your home, office, or wherever. Want a hardwood floor without having to worry about dry rot or constant water damage? Want tile without having to replace it every so often due to the frailty of the surface? If you’re looking for these textures, or a number of others, Decorative Stained concrete can probably give you what you’re looking for

There are services available to have your stained concrete floor colored and textured to resemble almost anything you can put on a floor. Rich and lifelike colors will give new life to your concrete slab, and set it up to fit the decor of the rest of your home, office, or wherever. Want a hardwood floor without having to worry about dry rot or constant water damage? Want tile without having to replace it every so often due to the frailty of the surface? If you’re looking for these textures, or a number of others, Decorative Stained concrete can probably give you what you’re looking for

1) They resist pet stains and odors.

1) They resist pet stains and odors.

5) You can heat them.

5) You can heat them.